First of all, there’s more than one way to set up a garage workshop because every handyman and mechanic has different interests, resources, tools, and needs. The trick is to learn how to set up a garage workshop that will work the best for you and your space.

Prepare for Your Workshop

Take measurements of your existing space to include the storage area, tools area, work area, and main shop. You may not have all of these areas, but measure the ones that you do have. Now is the time to sketch your garage as it exists and mark up with your measurements. Many times, just the exercise of sketching will show you the inconsistencies in your arrangement or layout. Ensure you include the windows, power sources, doors, lights, and fixtures like cabinets and shelves.

Photo by kievstock on Shutterstock

Tool Wishlist

Now is time to get started on the list of all the tools, resources, accessories, and systems you would like to get in your workshop over the next few years. This will also include dust collection areas, drying areas, lumber storage, finishing booths, and tool boxes.

Photo by Viacheslav Lakobchuk on Adobe Stock

Basic Handyman Tools

• Jigsaw

Photo by auremar on Adobe Stock

• Table or small workbench

• Circular saw with combination blade

Photo by guruXOX on Shutterstock

• Corded drill (ideally reversible with variable speed)

Photo by 063592541m on Dreamstime

• Pad-type power sander

• Shop vacuum

• Garage broom

• Cordless drill/driver

Photo by Philipimage on Adobe Stock

• Basic bit set and accessories

Intermediate Handyman Tools

• Drill press

Photo by AntonioDiaz on Adobe Stock

• Scroll saw

Photo by RitterSven on Adobe Stock

• Bench grinder

Photo by Philipimage on Adobe Stock

• Tool sharpening center

• Reciprocating saw

Photo by digitalreflect on Adobe Stock

• Random orbit sander

• Hammer drill

Photo by Sergey Ryzhov on Adobe Stock

• Router and router table

• Dust collection Center

• Biscuit joiner

Photo by Patricia Hofmeester on Dreamstime

• Table saw

• Power miter saw

• Belt sander

Photo by Carlos Andre Santos on Adobe Stock

Advanced Handyman Tools

• Power planer

Photo by Lightkeeper on Dreamstime

• Band saw

• Jointer

• Spray booth/HVLP sprayer

• Sliding compound miter saw

• Air compressor

Photo by Mohamed Ahmed Soilman on Dreamstime

• Air tools

• Sanding station

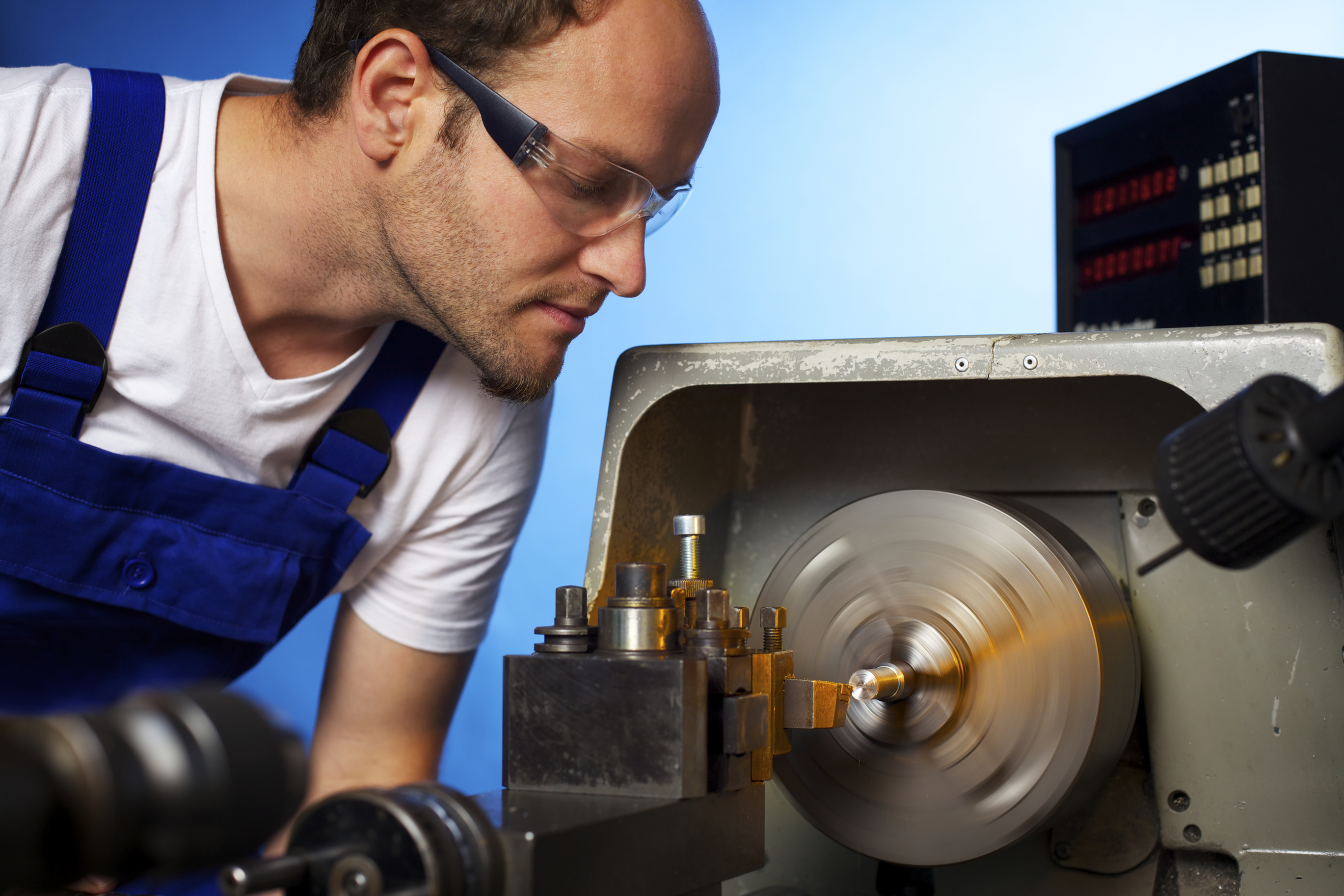

• Lathe

Photo by lichtmeister on Adobe Stock

• Welding equipment

• Shaper

Optimize Your Space

Now look at your existing shop space and your wishlist. Is there anything that won’t fit? If this is the case, amend the wishlist or figure out smart ways to combine multiple single-purpose tools into a purchase for a multi-purpose tool or workspace to conserve space in the shop. As you’re planning your workshop, pay attention to your space and make sure the space you allocate for each tool allows for effective and safe operation with ample room.

Photo by bernardbodo on Adobe Stock

Increase Electrical Service

Since a workshop is constantly evolving with the skills and needs of a handyman, the space will need changing at some point to accommodate those changing needs. Most cases will require you to increase the electrical service for major tools and equipment you have in your work area by adding 20-amp lines and maybe even a 240-volt service for a state-of-the-art shaper, table saw, or radial-arm saw.

Out of Sight, Not out of Mind

A lot of power tools in this day and age come with removable lock keys. If the key isn’t in the ON/OFF switch, then the tool can’t be turned on. Be sure to have a convenient spot for storing removable tool lock keys so they are readily available but still out of the sight from the tool to prevent accidents and thefts.

Magnet Retrieval

Keep a magnet handy to catch all those loose washers, screws, nails, and drill bits that manage to find their way onto the floor with the debris and sawdust shavings. A magnet makes it much easier to retrieve loose metal pieces and put them back in their respective containers.

Photo by Bokgallery on Dreamstime

The Standard Workshop Wallpaper

When it comes to “wallpaper” in the workshop, the best kind is pegboards. Standard perforated workshop pegboard provides a great way to organize your tools and hardware. Hanging devices for your pegboard can be purchased individually, as a whole system, in different configurations and sizes, or for specific tools and equipment.

Photo by photology1971 on Adobe Stock

Gloves, Gloves & More Gloves

Gloves are a necessity for every handyman and every shop — at least for those who want to protect their most important tool of the trade: their hands. Ensure you keep an ample supply of good-condition gloves of every type: heavy work gloves, heavy cotton or jersey style gloves, disposable plastic gloves, rubber-dipped masonry gloves, household type rubber gloves, and neoprene rubber gloves.

Photo by Goinyk on Adobe Stock

It doesn’t matter whether the area of your garage workshop is a stunning 5,000-square-foot space or you’re using a simple work surface in the laundry room, every handyman can ensure good tool maintenance practices are followed by using these techniques to keep their shop and tools in tip-top shape.